Department Projects

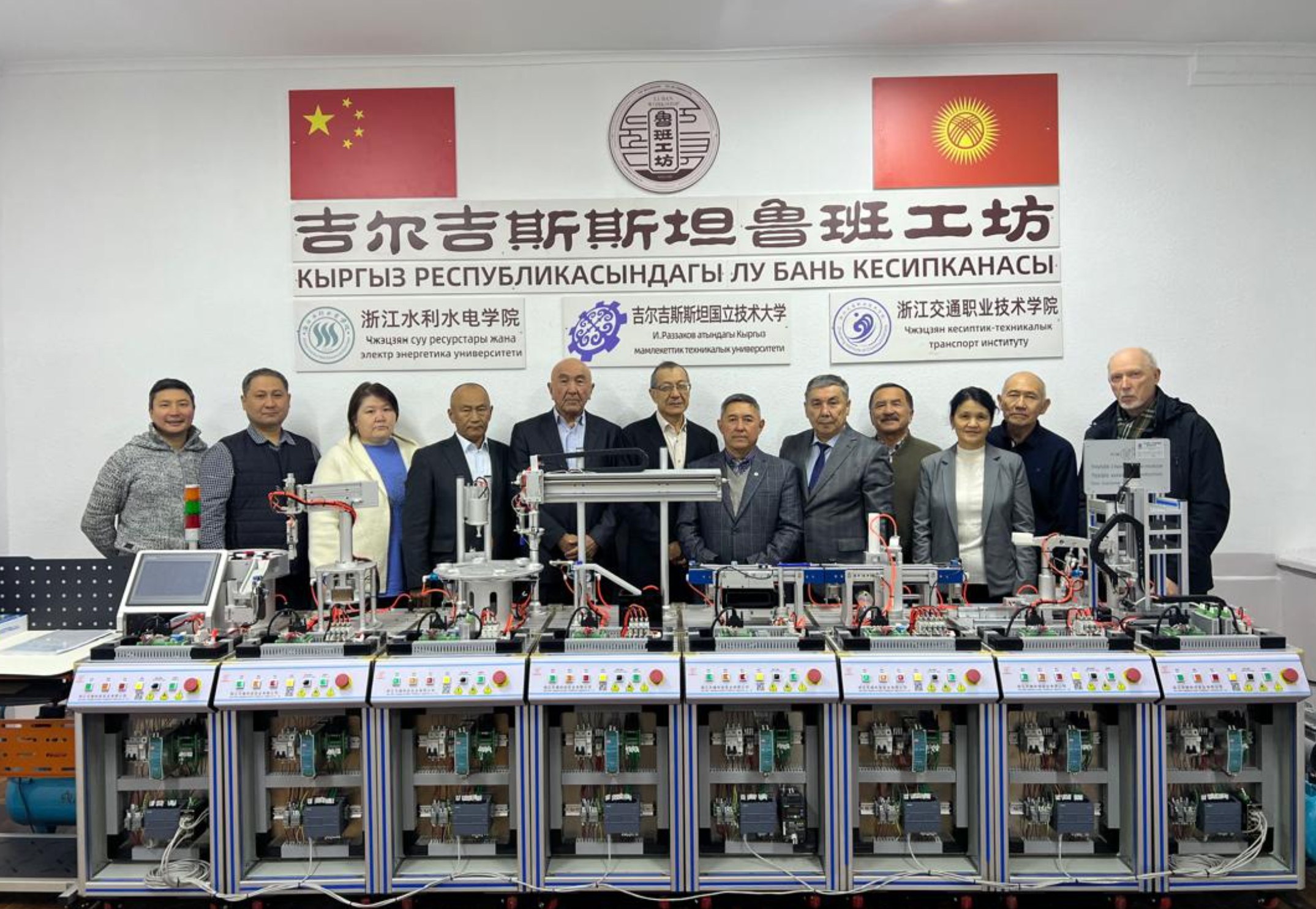

Lu Ban Workshop in Kyrgyzstan

The Lu Ban Workshop of the I. Razzakov Kyrgyz State Technical University (KSTU) is a joint center with Chinese universities and enterprises for training highly qualified personnel in engineering fields, improving skills based on Chinese technologies, and providing experience for the development of technical education in Kyrgyzstan. The Department of "Mechanical Engineering Technology" operates two laboratories: the Digital Manufacturing Laboratory and the CNC Material Processing Laboratory.

Key aspects:

Objective: To train specialists in demand in the mechanical engineering field using advanced Chinese approaches and international standards.

Collaboration: Implemented with the support of the government of Zhejiang Province of China, Zhejiang University of Water Resources and Hydropower, "Zhejiang First Hydropower Construction Group Co., Ltd.", and Beijing Chaoxing Group.

Directions: Based at the Department of Mechanical Engineering Technology, laboratories for "Material Processing Technology" and "Digital Manufacturing" have been established. The equipment of these laboratories includes:

A Flexible Automated Production System worth 80,500 USD;

A CNC Milling Machine worth 20,600 USD;

Universal Measuring Microscopes (UMM) worth 20,000 USD.

Project OZONIX

On December 4, 2025, the International IT Forum 2025 and an exhibition of innovative prototypes by FabLab Bishkek and KSTU were held at the I. Razzakov Kyrgyz State Technical University. A team of graduates and employees of the department participated in the forum. They became winners of the FabLab Bishkek business incubation program and received financial funding for their project. The team proposed a technology for extending the shelf life of perishable products using ozone, humidity control, and ultraviolet light. The solution aims to reduce food loss, increase farmers' profitability, and strengthen the region's food security.

Project "DEN 1-22 Installation for Manufacturing Plastic Products by Vacuum Forming"

Scientific Supervisors: Zh.M. Zhumaliev, Associate Professor of the "Mechanical Engineering Technology" Department; M.K. Sopoev, Senior Lecturer of the "Mechanical Engineering Technology" Department, I. Razzakov KSTU.

Executor: D.A. Tomilov, student of group MTM(b)-1-18.

About the project: Vacuum forming allows obtaining three-dimensional parts from sheet plastic. The plastic sheet is heated to a plastic state and replicates the shape of a prepared matrix. This technology is used for serial production since the matrix can be reused.

Due to the need to train mechanical engineering students in modern material processing methods, the idea arose to develop and manufacture a laboratory installation for vacuum forming of plastic products, as industrial installations are costly.

Funding: To implement this idea, they participated in a project competition at KSTU and won a grant of 39,000 soms.

All materials and components were purchased within the specified amount, manufactured, and assembled by hand in the workshop of the "Mechanical Engineering Technology" Department of I. Razzakov KSTU.

Operating principle: The material is fixed in a frame, after which the heating lamps and compressor are turned on. The lamps heat the material to a plastic state, and the compressor pumps air out of the receiver cylinder, creating a vacuum. A forming blank is placed on the vacuum grid. The plastic heated to plasticity lowers onto it, and the vacuum grid sucks the material, which in turn envelops the shape, creating the desired product.

Results: As a result of the research, a vacuum forming machine DEN 1-22 was designed and built for use in educational processes to conduct laboratory work in relevant disciplines. Using this machine, various parts and products can be made from plastics. The installation is located in the laboratories of the Mechanical Engineering Technology Department for conducting laboratory work.

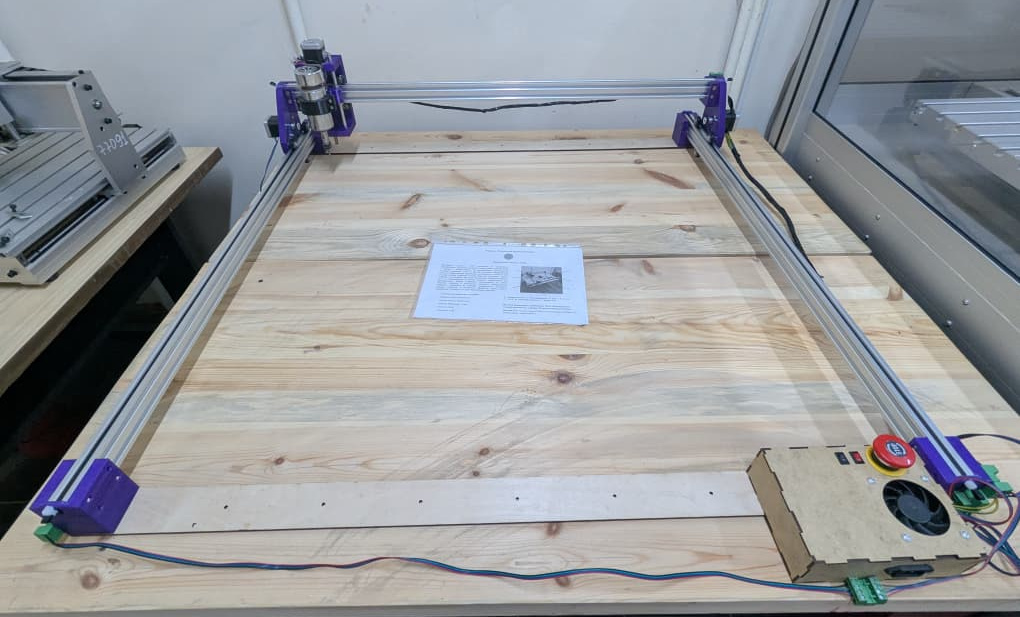

Project "Development and Assembly of a Desktop Four-Axis CNC Milling Machine"

Scientific Supervisor: Senior Lecturer of the "Mechanical Engineering Technology" Department, Dyikanbayeva Urpiya Mamatkadyrovna

Executor: Student of group MTMb-1-18, Tomilov Denis Aleksandrovich

About the project: Currently, CNC machines are widely used in industry. They speed up part manufacturing and combine speed with precision, as CNC equipment provides high accuracy in part production.

Funding amount: Thirty thousand six hundred soms (30,600 soms).

Project objective: To design a model of a four-axis CNC milling machine in SOLIDWORKS and assemble a four-coordinate CNC milling machine. Subsequently, to program the machine and conduct commissioning work so that students can familiarize themselves with this type of equipment and test it in practice by using it in laboratory work.

Justification and relevance: A CNC machine operates based on the coordinates of the control program and executes the assigned tasks. The operating principle of a four-axis CNC milling machine is based on numerical control using the G-code coordinate programming code. The machine moves along points in the X, Y, Z coordinate system according to the coordinate code. In our case, there will also be a rotary "A" axis, making the machine four-coordinate. A drawing, image, or 3D model is loaded into a program to create a control program, which generates G-code based on the coordinate system. This G-code is then loaded into the CNC machine, the material for processing is secured, zero is set on all coordinate axes, and the control program is launched.

Result: A four-coordinate CNC milling machine has been assembled, programmed, and commissioned. The machine is used in laboratory work for students; it is inexpensive, repairable, and capable of processing wood, plastics, and soft metals.